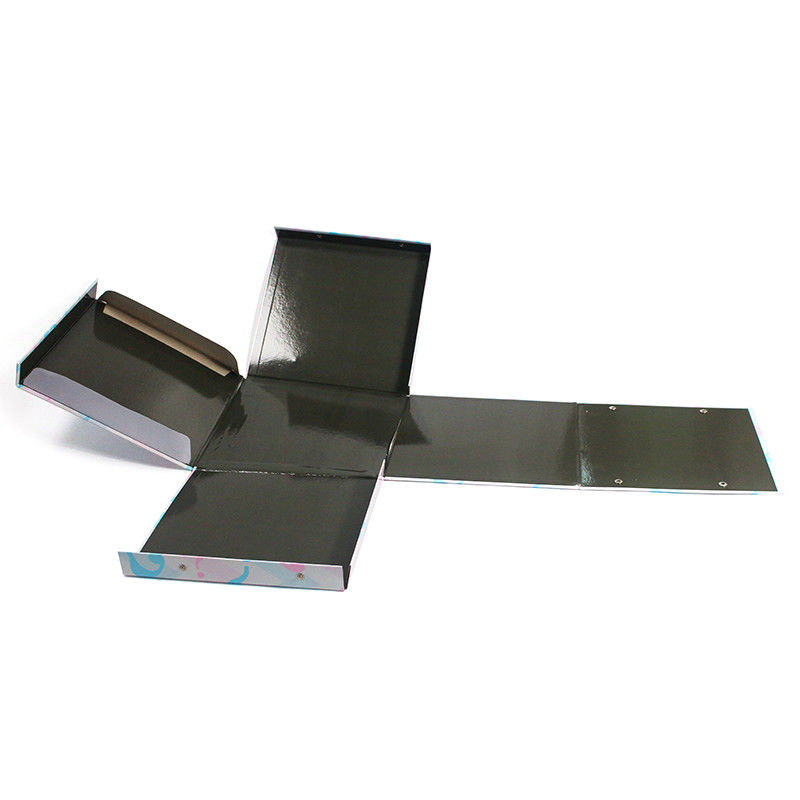

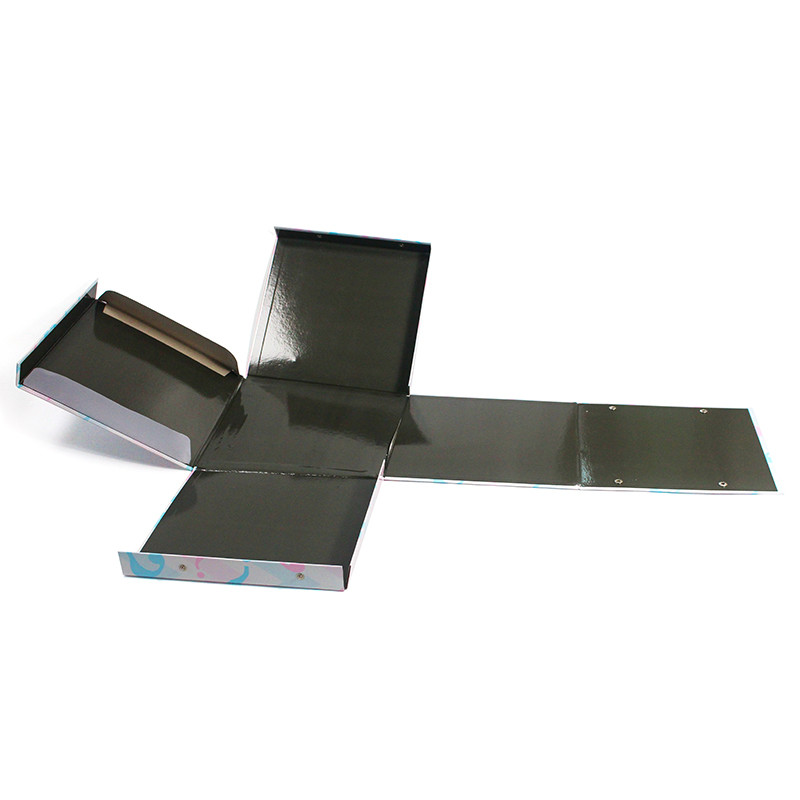

Product Description

| Surface Disposal |

Embossing,Glossy Lamination,Matt Lamination,Stamping,UV Coating,Varnishing |

|

Printing

|

CMYK or Panton |

| Size |

Custom;

|

| Shape |

Square;Cuboid;Custom |

| Feature |

Folding |

| MOQ |

500pcs |

| Shipping |

By Air;By Sea;By Land |

| After-sales Policy |

We will inspect it before shipment, please contact us if damage occurs.We will make compensation in the next order according to the damaged quantity. |

From Scratch: Analysis of the Whole Process of Customized Gift Box Packaging

Creating customized gift box packaging from scratch requires a thoughtful approach that goes beyond mere aesthetics. A well-designed gift box doesn’t just protect the product; it enhances the brand image, offers a memorable unboxing experience, and can even drive customer loyalty. Here’s a step-by-step analysis of the entire process of creating customized gift box packaging, from initial concept to final production.

1. Defining Your Packaging Goals and Brand Identity

The process begins by identifying the goals for your packaging. Ask yourself what you want the gift box to convey about your brand and the product inside. Are you aiming for a luxurious feel, an eco-friendly design, or a playful look? Understanding these goals is essential, as they will guide every design decision you make. At this stage, consider your brand’s identity and values and how these can be communicated through your packaging design.

2. Researching Market Trends and Analyzing Competitors

To create packaging that stands out, it’s helpful to research current packaging trends and analyze competitor designs. By understanding what’s popular and effective in the market, you can gain inspiration and insight into what appeals to your target audience. Analyzing competitor packaging can also help you identify what sets your brand apart and how you can emphasize this through unique design elements, colors, or materials that reinforce your brand’s identity.

3. Selecting the Right Materials

Material selection is a crucial step in the customization process, as it impacts both the appearance and functionality of the packaging. Options like rigid cardboard, corrugated board, or eco-friendly kraft paper each have unique qualities. For example, rigid cardboard gives a premium look and feel, while kraft paper appeals to eco-conscious consumers. Selecting the right material ensures that the box not only looks good but also aligns with your brand values and meets practical requirements for durability and protection.

4. Designing Key Brand Elements

At this stage, you begin designing the visual elements of the box, such as colors, typography, logos, and graphics. Colors should reflect your brand and evoke the right emotions—whether it’s sophistication, excitement, or serenity. Typography should be consistent with your brand’s tone and easy to read. Logos and graphics, meanwhile, can be used strategically to create a visual identity that’s unique to your brand. Experiment with finishes like embossing, foil stamping, or matte lamination to make these elements pop.

5. Prototyping and Testing

Once the design is finalized, creating a prototype allows you to see the packaging in physical form and make any necessary adjustments. This step is crucial for assessing the packaging’s functionality, durability, and aesthetic appeal. Testing the prototype also provides an opportunity to gauge the unboxing experience and ensure that all elements come together as intended. Feedback from team members or even select customers can help identify improvements before moving to full production.

6. Moving to Production and Quality Control

After the prototype has been refined, it’s time to move to full production. Working with reliable packaging suppliers ensures that quality standards are met. This phase includes a quality control process to verify that each box meets the design specifications and maintains consistency across batches. Quality control checks are essential to ensure that every box enhances the product’s presentation and brand image as intended.

7. Finalizing the Distribution and Unboxing Experience

The final step in the process involves preparing the packaging for distribution. Think about how the boxes will be stored, shipped, and presented to customers. The unboxing experience is a continuation of the brand story, so consider adding small touches like branded tissue paper, a thank-you card, or custom inserts. These details enhance the customer’s experience and leave a lasting impression, turning the packaging into a memorable part of the product.

In conclusion, the process of creating customized gift box packaging from scratch is a comprehensive journey that requires attention to detail, a deep understanding of brand identity, and a focus on functionality. By carefully following each step—from defining goals and selecting materials to designing, prototyping, and quality control—you can create gift box packaging that not only protects the product but also reinforces your brand’s image, creates customer loyalty, and delivers a memorable unboxing experience.

Q1: Are You Manufacturer or Trading Company? Are You Manufacturer or Trading Company?

A1: We are the 100% Manufacturer specialized in printing & packaging business more than 13 years with 300 skilled workers and 15 experienced sales, with a plant area of more than 15000 square meters.

Q2: How to custom my own box?

A2: We can send the template for you to put the design in or our engineers can support the design for you.

Q3: Is sampling cost refundable?

A3: Yes, the sampling cost is refundable when bulk order placed on us.

Q4: What is the lead time for sample and Mass Production?

A4: We will take 3-5 days for the sample order. The lead time for mass production based on your orders quantity, finishing, etc.,usually 7~15 working days is enough.

Q5: What payment methods do you accept?

A5: Alibaba assurance order, T/T, L/C, West Union, MoneyGram.

Q6: why should you buy from us not from other suppliers?

A6: Over 15000 square meters plant area; has the most advanced and complete equipments; has more than 300 senior talents; fully complied with ISO9001, ISO14001, GMI, SMETA.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!