Product Description

| Surface Disposal |

Embossing,Glossy Lamination,Matt Lamination,Stamping,UV Coating,Varnishing |

|

Printing

|

CMYK or Panton |

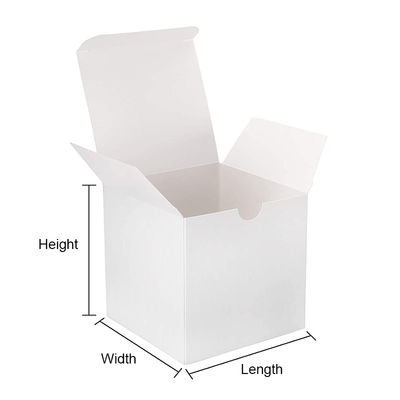

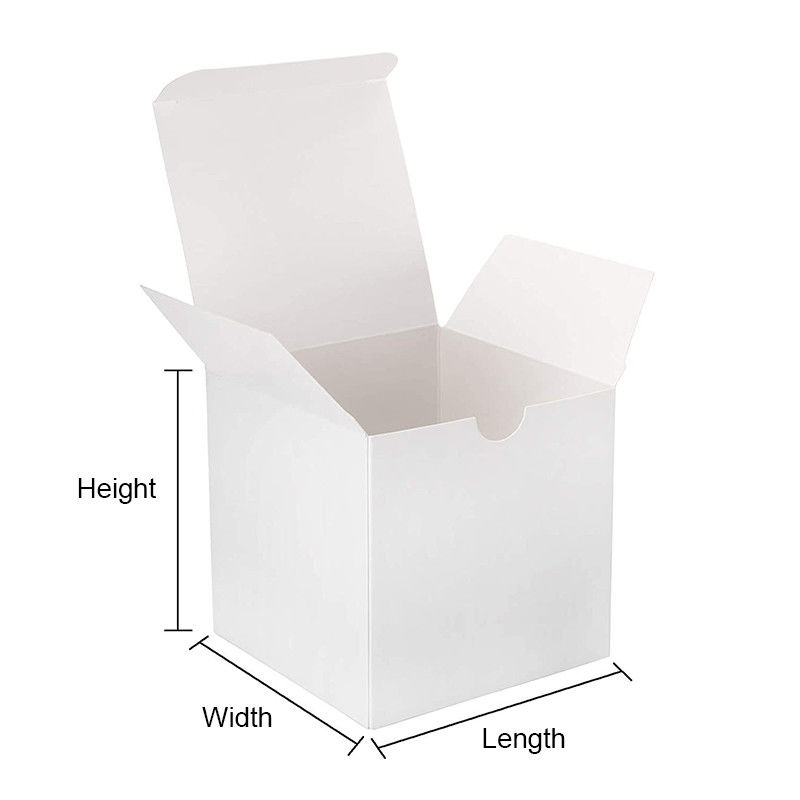

| Size |

Custom;

|

| Shape |

Square;Cuboid;Custom |

| Feature |

Folding |

| MOQ |

500pcs |

| Shipping |

By Air;By Sea;By Land |

| After-sales Policy |

We will inspect it before shipment, please contact us if damage occurs.We will make compensation in the next order according to the damaged quantity. |

How to Choose Between Corrugated and Solid Paper for Custom Boxes

When it comes to packaging, the choice of material can significantly affect both product protection and presentation. For businesses considering custom boxes, understanding the differences between corrugated and solid paper is crucial. Each type has its unique features and advantages, making them suitable for different applications. This blog will explore how to choose between corrugated and solid paper for custom boxes.

1. Understanding the Basics of Each Material

Corrugated paper is made up of three layers: an inner and outer layer of solid paper with a wavy, fluted layer in between. This construction provides strength and durability, making corrugated boxes ideal for shipping and protecting heavier items. On the other hand, solid paper, typically a single layer, is smoother and offers a more polished look, making it great for retail packaging and displays. Knowing these fundamental differences can help businesses determine which option is better suited for their specific needs.

2. Assessing Product Weight and Fragility

The nature of the product being packaged is a significant factor in deciding between corrugated and solid paper. If you are shipping heavy or fragile items, corrugated boxes are often the better choice due to their structural integrity. The fluted layer adds cushioning and resistance to pressure, helping to prevent damage during transit. Conversely, if you are packaging lightweight or less delicate products, solid paper can provide an attractive presentation without the bulk, making it a more cost-effective option.

3. Evaluating Shipping and Storage Needs

Another important consideration is how the boxes will be used throughout the supply chain. For businesses that frequently ship products, corrugated boxes offer superior protection against the rigors of transportation. Their durability makes them suitable for stacking and storing without losing shape or integrity. However, if the boxes are primarily for in-store displays or customer gifts, solid paper can create a visually appealing presentation that aligns with branding efforts, while also being easier to store due to its lightweight nature.

4. Considering Environmental Impact

Sustainability is a growing concern for many consumers and businesses. When choosing between corrugated and solid paper, it’s essential to consider the environmental impact of each material. Both types can be made from recycled paper, but corrugated boxes are often more recyclable due to their layered structure. If eco-friendliness is a priority, sourcing materials from sustainable sources and ensuring recyclability will be key factors in your decision-making process.

5. Cost Considerations

Budget constraints are always a consideration when choosing packaging materials. Generally, solid paper boxes are more affordable than their corrugated counterparts, especially for small production runs. However, the long-term cost-effectiveness should also be evaluated. While corrugated boxes may have a higher upfront cost, their durability can result in fewer damaged products and returns, ultimately saving money in the long run. Assessing both initial costs and potential savings is crucial for making an informed decision.

6. Aesthetic Appeal and Branding Opportunities

Packaging is not just about protection; it’s also about presentation. Solid paper offers a smooth surface that is ideal for high-quality printing and finishing options, making it perfect for branding and marketing. Businesses can use solid paper boxes to showcase their logo, colors, and design elements effectively. While corrugated boxes can also be printed, the texture may not provide the same high-end finish. If aesthetics are important for your brand image, solid paper might be the way to go.

Conclusion: Making the Right Choice for Your Custom Boxes

Choosing between corrugated and solid paper for custom boxes involves evaluating various factors, including product weight, shipping needs, environmental impact, cost, and aesthetic appeal. Understanding the strengths and limitations of each material can help businesses make an informed decision that aligns with their packaging requirements and branding strategies. By carefully considering these elements, companies can select the right type of custom box that not only protects their products but also enhances their brand identity and customer experience.

Q1: Are You Manufacturer or Trading Company? Are You Manufacturer or Trading Company?

A1: We are the 100% Manufacturer specialized in printing & packaging business more than 13 years with 300 skilled workers and 15 experienced sales, with a plant area of more than 15000 square meters.

Q2: How to custom my own box?

A2: We can send the template for you to put the design in or our engineers can support the design for you.

Q3: Is sampling cost refundable?

A3: Yes, the sampling cost is refundable when bulk order placed on us.

Q4: What is the lead time for sample and Mass Production?

A4: We will take 3-5 days for the sample order. The lead time for mass production based on your orders quantity, finishing, etc.,usually 7~15 working days is enough.

Q5: What payment methods do you accept?

A5: Alibaba assurance order, T/T, L/C, West Union, MoneyGram.

Q6: why should you buy from us not from other suppliers?

A6: Over 15000 square meters plant area; has the most advanced and complete equipments; has more than 300 senior talents; fully complied with ISO9001, ISO14001, GMI, SMETA.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!