Product Description

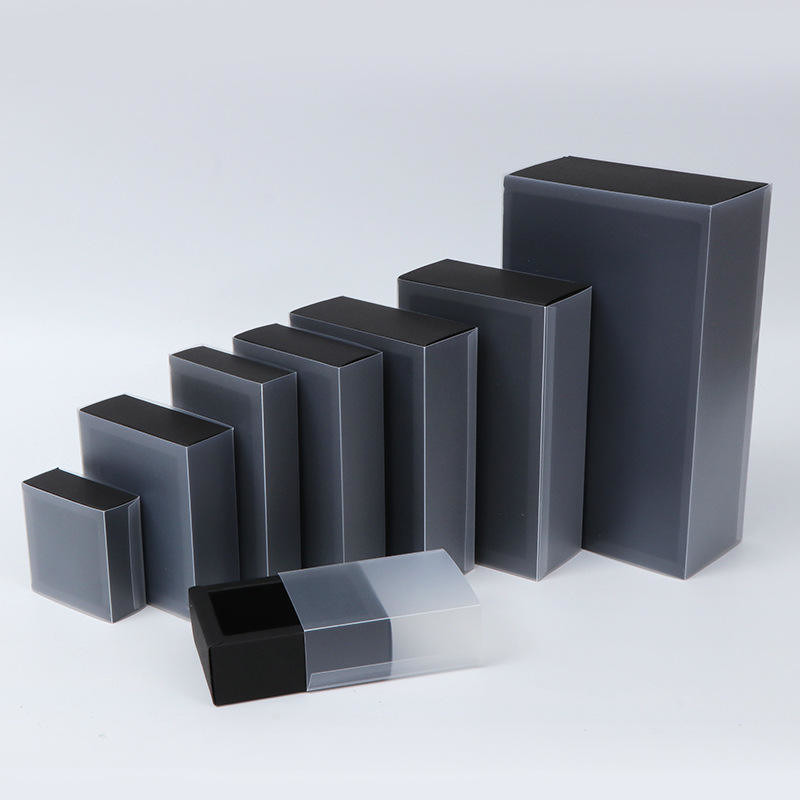

Custom Printing Plastic Sliding Sleeve Foldable Drawer Box For Socks

We are a professional book printing & packaging company based in China. Our major clients are based in NA, EU, and Africa.

Established in 2009, Shenzhen Lx Paper pack Printing Co., Ltd. is located in the Bao'an district, with a plant area of more than 15000 square meters, among more than 300 employees in the factory, 15 of whom are in the R&D team with more than 13+ years of experience in the industry.

Packaging Box Customization

|

Box Types

|

Corrugated box, kraft box, mailer box, cardboard box, art paper box, wine box, etc.

|

Box structure

|

Magnet box, folding box, lid and base box, drawer box, custom shape box, tube box, mailer box etc.

|

|

|

Gift box, cosmetic box, folding box, jewelry box, chocolate box, hamper box, flower box, etc

|

|

Matte or glossy lamination, embossing, hot stamping, spot UV, varnishing, Pantone color, etc.

|

|

Custom

|

Size (L*W*H), color (full color, pantone color), design (PDF, AI, PSD, CDR, etc.)

|

Product Photo

Printing Techniques for Kraft Packaging

Kraft paper boxes packaging is compatible with most modern printing machinery and techniques. Due to the thickness of kraft material, your inkjet and laser printers might not be the most suitable choice.

Just remember that the results will depend mostly on the printing material you use. Hence, take a close look at the quality of the paper. Make sure to assess its surface and determine whether it creases, cracks, or stains easily. Additionally, try to ask about its physical properties, such as its printing performance, absorption, and optical properties.

Many printing companies would use different printing techniques to achieve the desired colors and designs on the kraft paper boxes material.

Here are the most widely used printing techniques for kraft paper boxes packaging:

1. Flexography

Flexography is a common printing method used on kraft boxes, particularly stand-up pouches. However, it can be used to print on corrugated boards as well. It uses light-sensitive polymer instead of plates to print on kraft cardboard.

Modern flexography machines have built-in die-cut and lamination. This makes it easier to laminate or cut kraft boards. Just remember that die-cutting and laminating kraft boards might cost you extra because of their thickness.

2. Offset Printing

Another widely used printing method that works well on kraft boxes and other forms of kraft packaging is offset printing. Also called offset lithography, this method uses printing plates to transfer an inked image to a rubber blanket before printing it on a kraft material. The printing plates are made of zinc or aluminum.

This type of printing technique utilizes oil-based inks, which are suitable for highly absorbent kraft materials. Using oil-based colors, you can have full-colored designs on your packaging.

FAQ

Q1: Are You Manufacturer or Trading Company? Are You Manufacturer or Trading Company?

A1: We are a 100% Manufacturer specializing in the printing & packaging business for more than 13 years with 300 skilled workers and 15 experienced sales, with a plant area of more than 15000 square meters.fully complied with ISO9001, ISO14001, GMI, SMETA

Q2: How can I get a die cut or sample? What is the lead time for sample and Mass Production?

A2:

1. We normally provide a die cut in 24 hours, after getting confirmation on your artwork, we will provide a sample in 1-7 working days.

2. The lead time for mass production based on your orders quantity, finishing, etc., usually 7~15 working days is enough.

Q3: Can you design boxes?

A3: Yes. We can design boxes for you. It includes box structural, insert, box outside artwork, box style, and more. You just provide pictures, a logo, etc. Others, we can do for you. Our professional team provides a whole packaging solution for you.

Q4: How to make sure all the box quality is good?

A4: Our QC workers check each box one by one very carefully and they put their QC numbers into master cartons. It is better for us to track each product's quality.

Q5: Can you assemble my products into the boxes?

A5: Yes. We can. If you purchase rigid boxes in our company, we suggest you ship the inside products to our factory, then we assemble the products into the boxes. If you purchase cardboard boxes in our company, we suggest that we ship the cardboard boxes into your product supplier to pack.

Q6: What payment methods do you accept?

A6: Alibaba assurance order, T/T, L/C, West Union, MoneyGram.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!